Preheaters and heating systems

Lube oil and coolant preheater

Thermal oil and steam preheating system

Heavy fuel oil preheater

Fuel heater for palm oil and bio diesel

LK-Preheaters and Heating Systems have proven themselves for many decades in the field. They are constantly changing according to current customer specifications. LK Heating Systems are used to preheat Steam- and Gas Turbines, Diesel Engines and Mechanical Drives for Stationary, Mining and Marine applications. The Heating Systems are ideal to heat fuel, coolant and oil, but can also be configured for process heating in the petrochemical and refinery industry.

LK-Preheating and Heating Systems are designed with distinctive features second to none. Even the basic designs offer technical extras that ensure a reliable and durable operation. That’s why LK- Heating Systems are technically in the lead.

Engineering and Production “Made in Germany”:

- We prefer to use steel pipe, instead of plastic hoses.

- We measure the temperature right in the medium, rather than hiding the thermostat in the element enclosure.

- We only use capillary tubes with liquid expansion mechanisms, rather than a bimetallic strip.

- We prefer to use industrial fittings, than plumbing components for household appliances.

- We do not use plastic enclosures.

- We use industrial switchgear instead of low-cost switches for domestic building applications.

- We are flexible and respond according to customer specific requirements.

- We deliver exactly what our customers need – no more, no less.

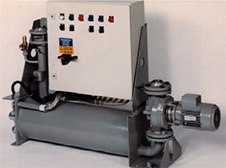

LK HeatHulk Engine Coolant Preheater up to 216 kW

LK HeatAnt Engine Coolant Preheater 3 – 12 kW

LK HeatHi Engine Coolant Preheater Tankheater from 1.5 – 12 kW

LK HeatMo Steam- and Thermaloil Preheater up to 300 kW

Preheating and Treatment of bio fuel, diesel and HFO.

Based on many years of experience and consistent advancement in the area of fuel system, we are able to design custom solutions for each individual process of your fuel system. We achieve this with maximum operational safety, paired with special attention for the system, to minimize wear and tear. After all, an optimized fuel treatment system and a gentle and gradual fuel heating process, lead to a better utilization of the fuel.